Custom Uniform Purchasing - Risks and How to Avoid Them

Custom uniforms can be a great way to create a professional and unified image for your sports club, school, work team or organisation. Custom uniforms are worn by almost all organised-team sports in Australia plus many school students and in many workplaces.

The fact that this is possible is thanks to a major innovation in garment production called sublimation. Sublimation in clothing means that sports clubs, work places and schools can have completely unique uniforms, with full customisation of colour, design, logos and printed text.

Not only are the finished garments unique, they are produced and delivered in a 4-6 week timeframe. This offers amazing flexibility for customers if you compare this to the normal production time for clothing. The flip side of a made-to-order production process in very fast

However, there are also some risks involved in the custom uniform purchasing process. Here's a breakdown of some potential pitfalls and how to navigate them:

Risk: Poor Fit and Quality

- Issue: Uniforms are ordered without enough time to check sizing and quality. Often it is not possible to check the correct sizing for the people who will be wearing the uniforms.

- Consequence: Incorrect-fitting uniforms lead to unhappy team members and can impact performance, it is also a waste of money for your organisation and an administrative headache.

- Avoidance:

- Thorough Sample Review: Always check physical samples from your uniform supplier. If this isn’t possible due to timing, ask for photos of their products and the names of other customers that you could check in with.

- Clear Specifications: Ask for clear and detailed specifications for fabric, weight, and construction to the uniform supplier. All quality suppliers will be very happy to provide you this information.

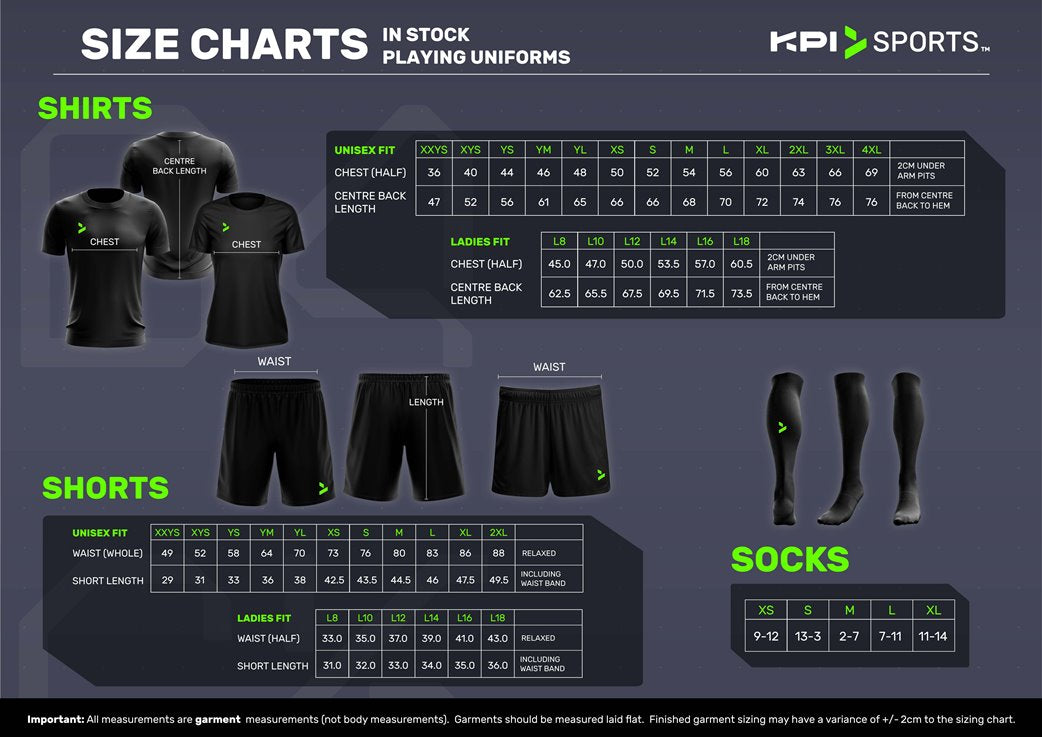

- Size Samples: If possible, ask to borrow a sizing kit or size samples from your supplier. If that’s not possible, ask for size charts for the specific products you are going to purchase. Be sure to read the fine print on size charts to make sure you are comparing the correct measurements.

Risk: Design Miscommunication

- Issue: The designs on custom uniforms can be very detailed and include a lot of important information, such as brand logos, brand colours as well as complex design patterns. Depending on timing, this can lead to the risk of errors in interpreting the design. Also, because the artwork mock ups provided by uniform suppliers are visual representations of garments, it is not always easy to imagine how the uniforms will look on real human bodies. This can lead to mis-matched expectations of the final product.

- Consequence: If the final uniforms do not match your vision, or do not represent your brand correctly, there is a risk of unusable product, wasted time and money.

- Avoidance:

- Detailed Design Mockup: Work with the uniform company to create a detailed mockup of the design before placing an order. Be sure to read the communication about designs and any fine print, especially about colours and design elements.

- Clear Communication: Clearly communicate your desired colours, logos, and any specific design elements. If you’re not sure something is right, ask again. If you’re really uncertain, ask if they have another customer with a similar design, can they share photos of the finished product?

- Multiple Revisions: Don't be afraid to request revisions until you're happy with the final design. Although this will take extra time, it is always better to make sure it is right before the production process starts.

Risk: Extended Lead Times

- Issue: Custom Uniforms are provided to very short timeframes, usually involving expedited design, production and shipping. This means that a delay to any part of the process, even if short, can impact customer’s expected delivery and overall experience.

- Consequence: Uniforms might not arrive on time, disrupting operations or events.

- Avoidance:

- Clear Deadlines: Clearly communicate your desired delivery date to the uniform company and factor in potential delays. If the uniform supplier expresses concern about achieving the timeframe, work on a back up plan, or explore alternatives.

- Order Early: Of course, this is the best insurance against delays. Particularly important for large orders or those with complex designs, order well in advance to avoid last-minute stress.

- Consider Backup Options: Have a backup plan in case of unforeseen delays, such as uniforms from last year or in-stock uniforms. Your uniform supplier should have more ideas about back-ups, depending on your situation.

Risk: Hidden Costs

- Issue: Because of the complexity of custom uniforms, pricing can vary depending on quantities ordered as well as details within designs, and this can vary between different suppliers.

- Consequence: The final price might be higher than you anticipated if a supplier has not clearly set out the detailed costs.

- Avoidance:

- Transparent Pricing: Get a written quote upfront that outlines all costs, including setup fees, embroidery charges, and any minimum order requirements.

- Compare Prices: Obtain quotes from several uniform suppliers to ensure you're getting a competitive price.

- Read the Fine Print: Carefully review the contract before signing to understand any cancellation policies or return restrictions.

By being aware of these potential risks and taking steps to avoid them, you can ensure a smooth custom uniform purchasing process that delivers high-quality uniforms that represent your brand well.

TAGS: